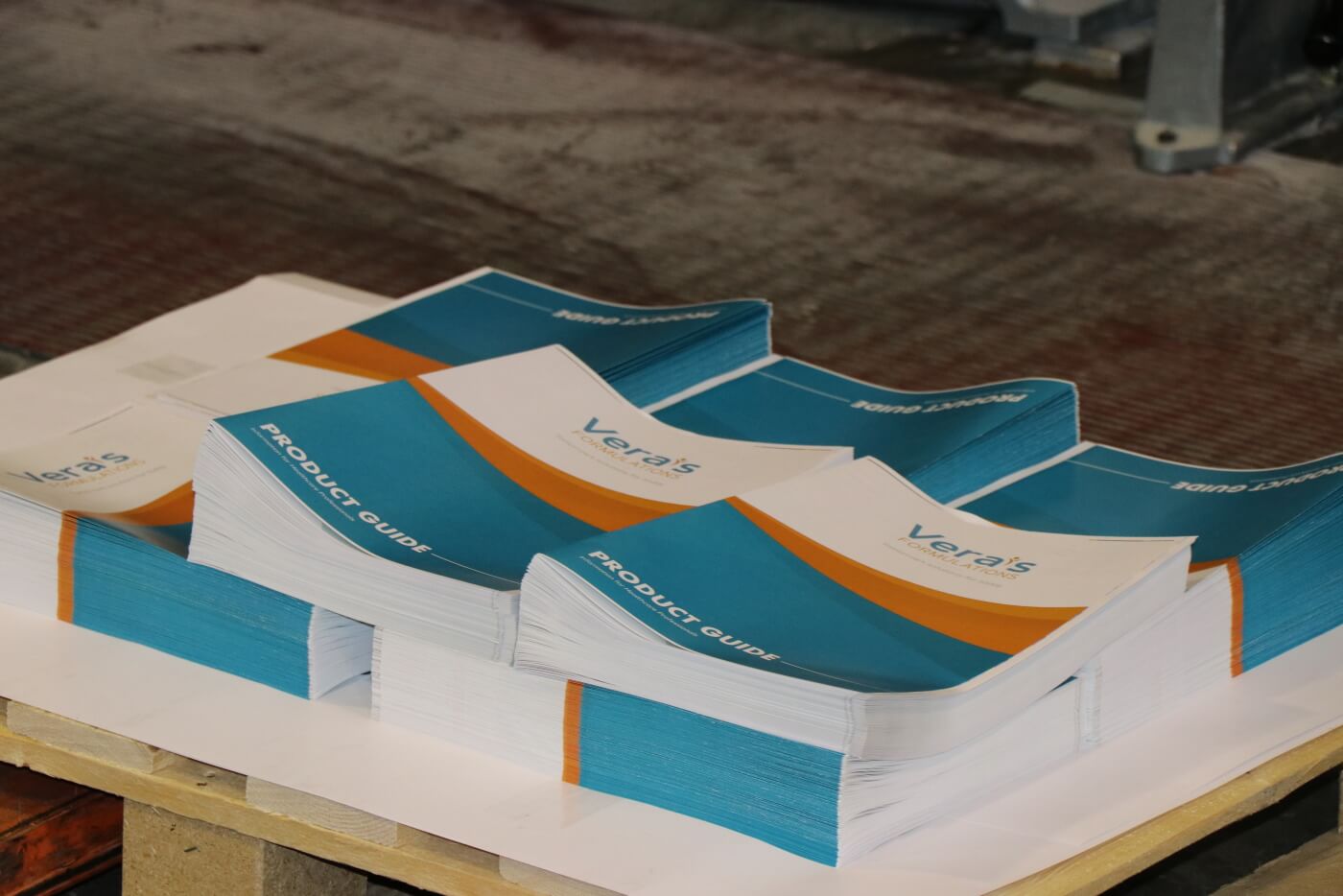

Saddle Stitching booklets in Brisbane is the process of producing beautiful booklets.

This saddle stitching process involves wire stapling folded pages to create a spine – to create a booklet. This process differs from a burst bound book which is glued.

The Saddle Stitching machine for larger print runs at Screen Offset Printing at Geebung in Brisbane, will saddle stitch a booklet anywhere between A6 and tabloid size (smaller newspaper).

The ‘saddle’ name of the process comes from the sheets being saddled on the machine as they are collated along the production line, before being stapled along the saddle.

The Saddle Stitching machine collates folded sections, stables (stitches) them and then trims the pages to size. Out the end comes a finished booklet.

The machine has six stations which can take six different folded section plus a cover feeder.

Up to 100 pages can be put through the machine to form a booklet.

There is also no wastage in the production process with the trimmed paper directed into a recycling bin.

This particular machine stationed on the main production floor at Screen Offset Printing is mainly employed for offset printing jobs.

Whether jobs are printed on the Komori Offset Printer or Screen Offset Printing’s Ricoh C9100 Digital Printer comes down to the size of the job.

“There’s a break-even point of which printing a job offset and then using the offline binders becomes more cost effective”, Screen Offset Printing Managing Director Gerard Davis said.

“Generally, we look at for a saddle stitching book above a 1,000 where 750 books are more cost effective for clients, digitally”.

Screen Offset Printing’s Brisbane based professional and friendly sales staff will provide you with the best recommendation.

Screen Offset Printing is your printing solution specialist.

Call Screen Offset Printing today on (07) 3265 1900 today, request a quote via our website or drop into the office at 202 Robinson Road, Geebung Brisbane.